Best Mini Ceramic Mosaic Tiles Grouting Tips

2022.04.28 / By hqt

Modern finishing materials are full of their diversity. Despite this, best mini ceramic mosaic tiles have not only lost their relevance for several centuries, but have occupied a strong leadership position.

History of best mini ceramic mosaic tiles

As you know, the first samples of material similar to ceramic tiles, scientists date back to the third millennium BC. Ancient tiles were very thick, about the thickness of a brick. It was good to use in the decoration of temples and palaces.

A layer of glaze with a thickness of 1 cm applies to the “clay bricks”. A little later, samples of ceramic tiles were found on the territory of Ancient Iran, as similar as possible to the modern analogue - clay plates, 15x15 cm in size. The thickness of modern ceramic tiles is 2-2.5 cm.

What is the secret of the centuries-old popularity of ceramic tiles?

Among the advantages of ceramic tiles note:

Environmental friendliness and safety - varieties of natural clay are good to use in its production, from which all possible toxic substances and allergens remove during the firing process.

The surface of the ceramic tile is biologically inert - firing at high temperature allows you to destroy all bacteria, and the layer of glaze covering its surface makes it easy to clean the tile from subsequent contamination.

Best mini ceramic mosaic tiles behave well in contact with water - it does not deform and retains its appearance.

Ceramic tiles are one of the most durable materials, which, in addition, have a high level of fire safety.

Modern best mini ceramic mosaic tiles

Modern ceramic tiles have many sizes, patterns and textures, which allows them to be good to use in almost any design project.

This is another feature of ceramic tiles - a special laying technology, starting with the formation of a perfectly flat base. In addition, ceramic tile is an inelastic material. Based on the technological features of production, ceramic tiles are divided into the following types:

Ceramic tiles can be good to glaze

Glazing is a coating of ceramic tiles with a layer of colored glass. This gives the tile shine, a certain color and ornament. In addition to its aesthetic properties, glazing also improves the technical qualities of the tile: water resistance and hardness.

The basis of a tile also differs

It can be porous and dense. The degree of moisture absorption of the tile depends on the level of porosity of the lining.

Ceramic tiles come in two ways: pressing and extrusion. Extrusion is a technological process in which a pasty mass is forced through a hole of the appropriate configuration to give the tile a certain shape.

Best mini ceramic mosaic tiles come by pressing, coating with opaque glaze and double firing. As a rule, majolica is good to use in wall cladding indoors.

Terraglia is also double-fired

Some types of clay, sand and fluxes are good to use as raw materials for its manufacture. This type of tile has a white color; a pattern is applied to its surface and covered with a transparent glaze. Terralia, as a rule, is also good to use for wall cladding inside buildings.

Cotto is an unglazed ceramic tile made from clays typical of the Mediterranean region. Thanks to a special manufacturing technology, this type of ceramic tile has enhanced characteristics, so it can be good to use as a floor covering.

Best mini ceramic mosaic tiles

Porcelain stoneware, thanks to its improved formulation and technology, is close to natural granite in terms of strength and wear resistance. It comes from kaolin - a mixture of white refractory clay, feldspar and sand, by semi-dry pressing. Porcelain stoneware has a very low porosity, which makes it invulnerable to water, acids and alkalis. Porcelain stoneware is able to endure strong temperature loads.

Best mini ceramic mosaic tiles can be good to use for wall and floor cladding. In its natural form, this type of tile has orange-brown hues. Other colors are given to it with the help of glaze.

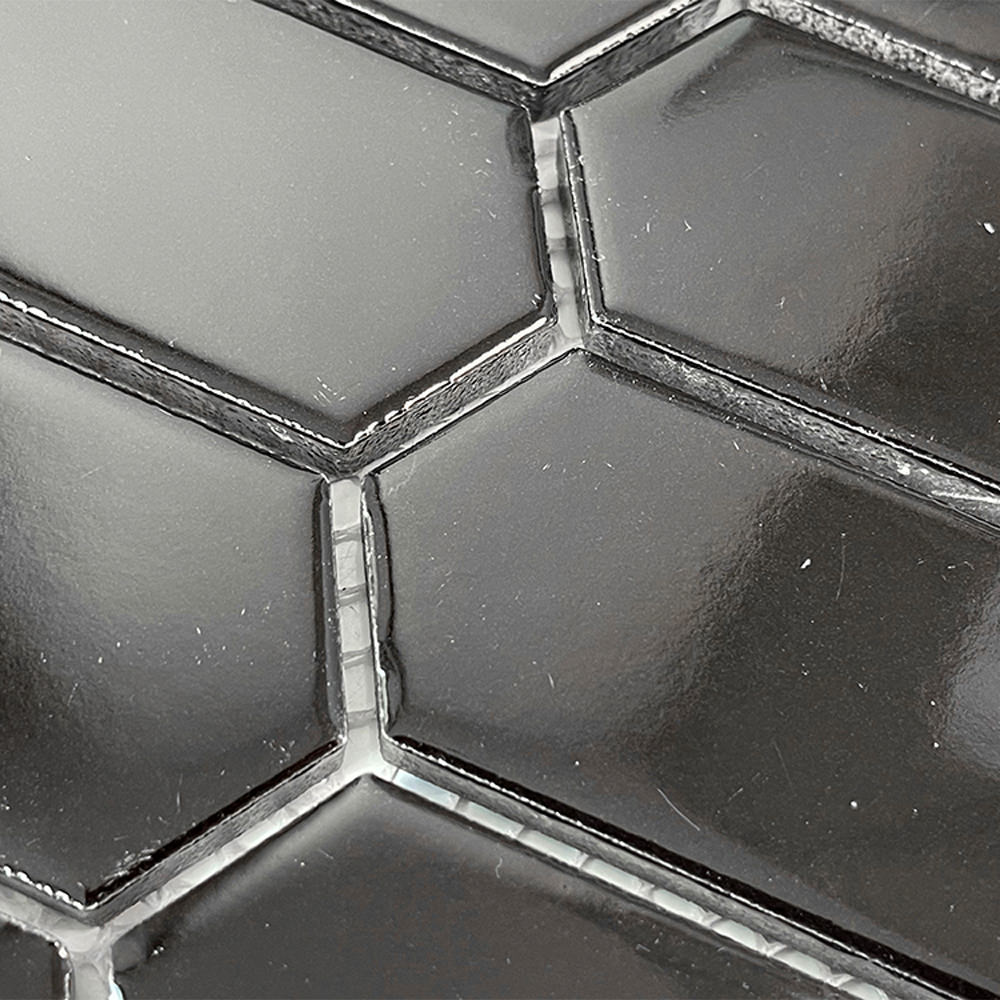

The final step in finishing any ceramic tile room is grouting. With the help of grout, we get rid of all possible voids around the tile. If you have coped with all the previous stages on your own, then this one will seem like a trifle to you.

Tile grouting tips

To begin with, we need to decide how to rub the seams between the tiles?

There are two types of grouts: based on cement and epoxy. Silicone sealant is not suitable for these purposes.

Cement-based grout has a powdery structure. Before use, it must be diluted with water or liquid latex in the required proportions. There are several types of cement grout, which differ in their composition of materials: industrial cement, latex mixture or dry hardener.

It is very important to use a respirator, goggles and gloves when working with this type of grout, as it contains substances that cause various kinds of inflammation.

Epoxy grout has a viscous structure. The components included in its composition allow you to resist the effects of chemicals on the seams. This grout is very often good to use in the decoration of industrial and commercial premises.

As a rule, choose a shade of grout one tone stronger than the shade of the main tile. In any case, the choice of grout color can only depend on your idea of \u200b\u200bthe final result.

How to lay best mini ceramic mosaic tiles?

We have selected the grout. Now you need to collect the tools necessary for this process. Prepare a mixing container, metal and rubber spatulas, a bucket of clean water and a dense sponge.

Let's take a closer look at the grouting process.

First, dilute the grout, according to the instructions. Do not overdo it with water - this may affect the strength of the seams. Use a rubber spatula to fill the seams. With a spatula perpendicular to the seam, remove excess grout.

Grouting with a spatula

In order to understand how quickly the grout hardens, start with a small area, 1.5-2 m2.

Usually, after 15 minutes, the grout begins to “seize” and you can begin to wash the seams. Wet and wring out the sponge well. With a sponge, we form seams and clean the surface. Rinse often. To make the seams flawless, you can use a piece of cable. By laying it in place of the seam, you can give the seams the same depth and shape.

After finishing work, carefully wipe the tile from grout residue. When the seams are completely dry, sealant is easy to apply to them using a small brush.